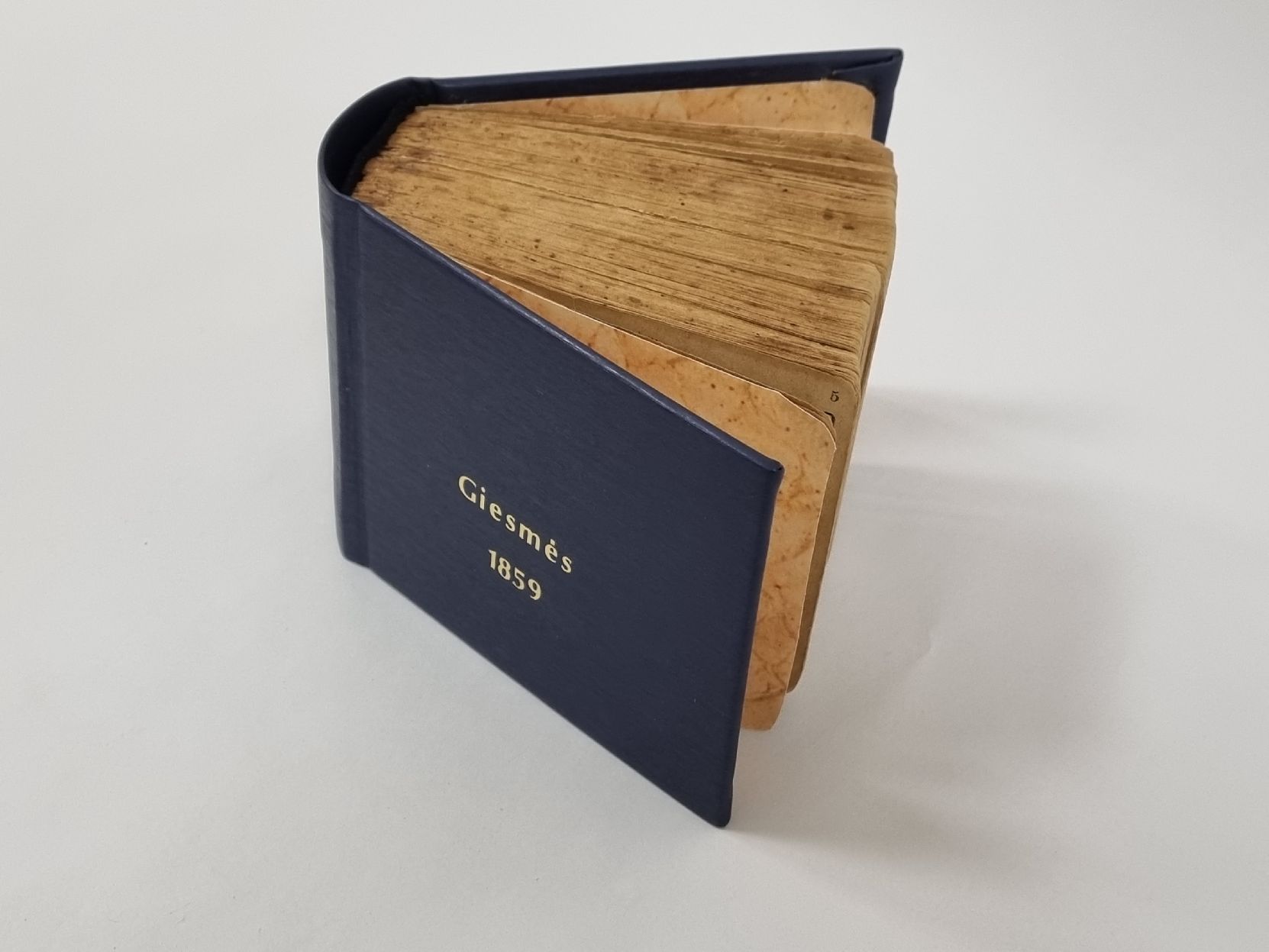

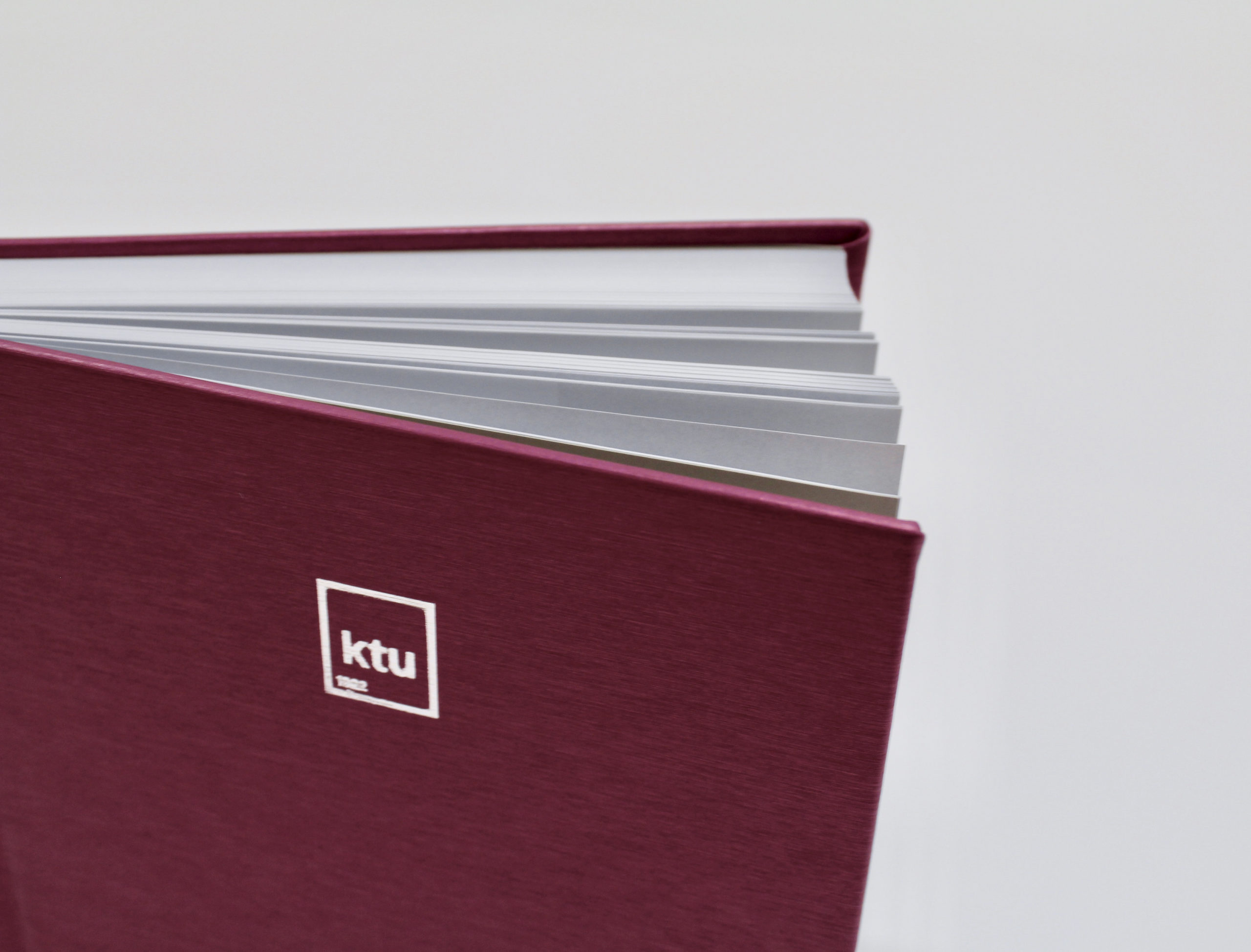

Our printing house is proud to be the only surviving printing house within an academic publisher’s structure. We are also one of the few printing houses with the capacity to hardcover bind publications with extremely low, low or medium print runs. We employ state-of-the-art digital printing technologies, and our extensive experience enables us to efficiently fulfil a wide range of customer requests without compromising on quality. We believe that we can contribute to the success of your business and personal projects. We offer competitive prices and can therefore provide the optimal solution for you.

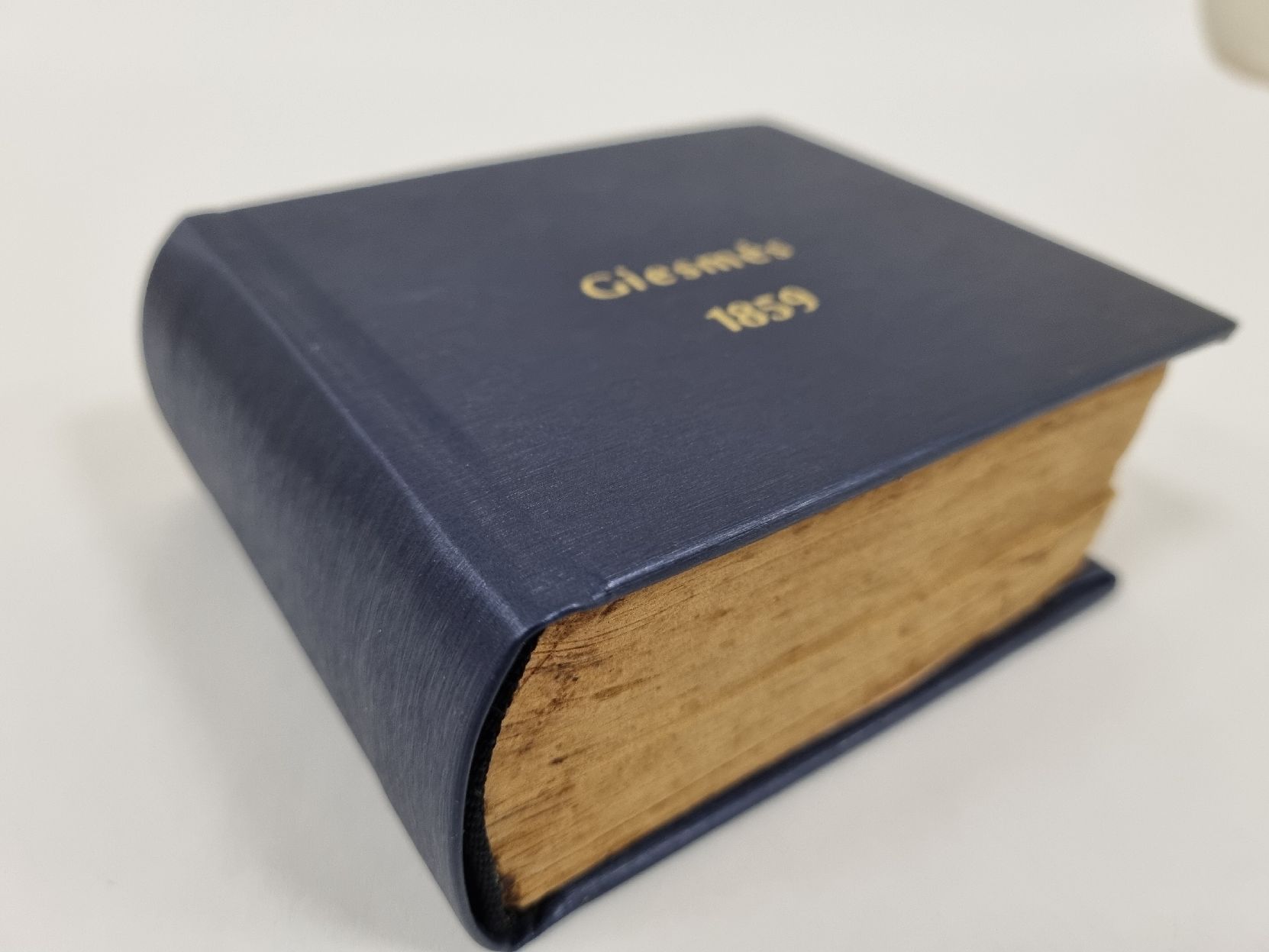

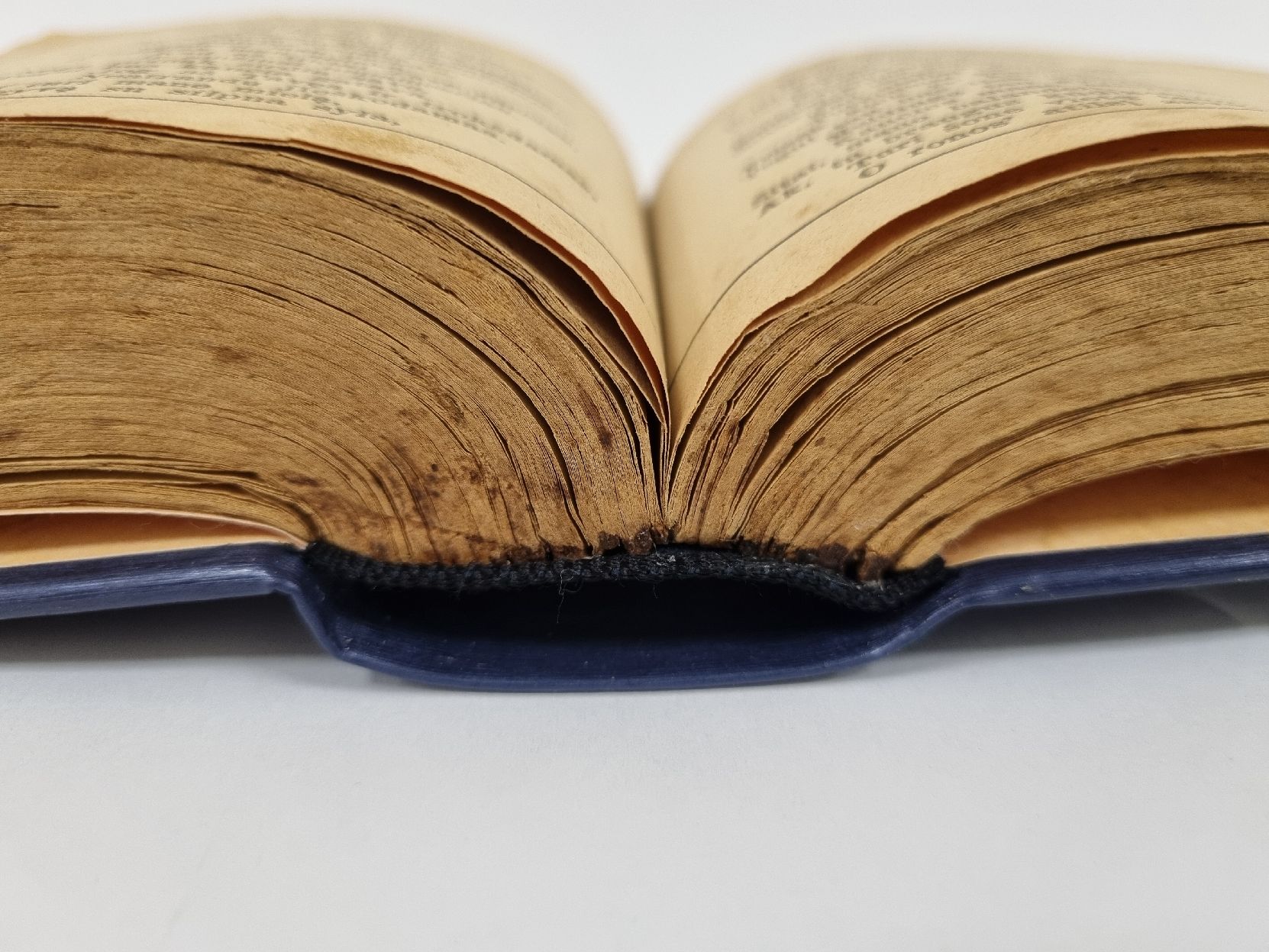

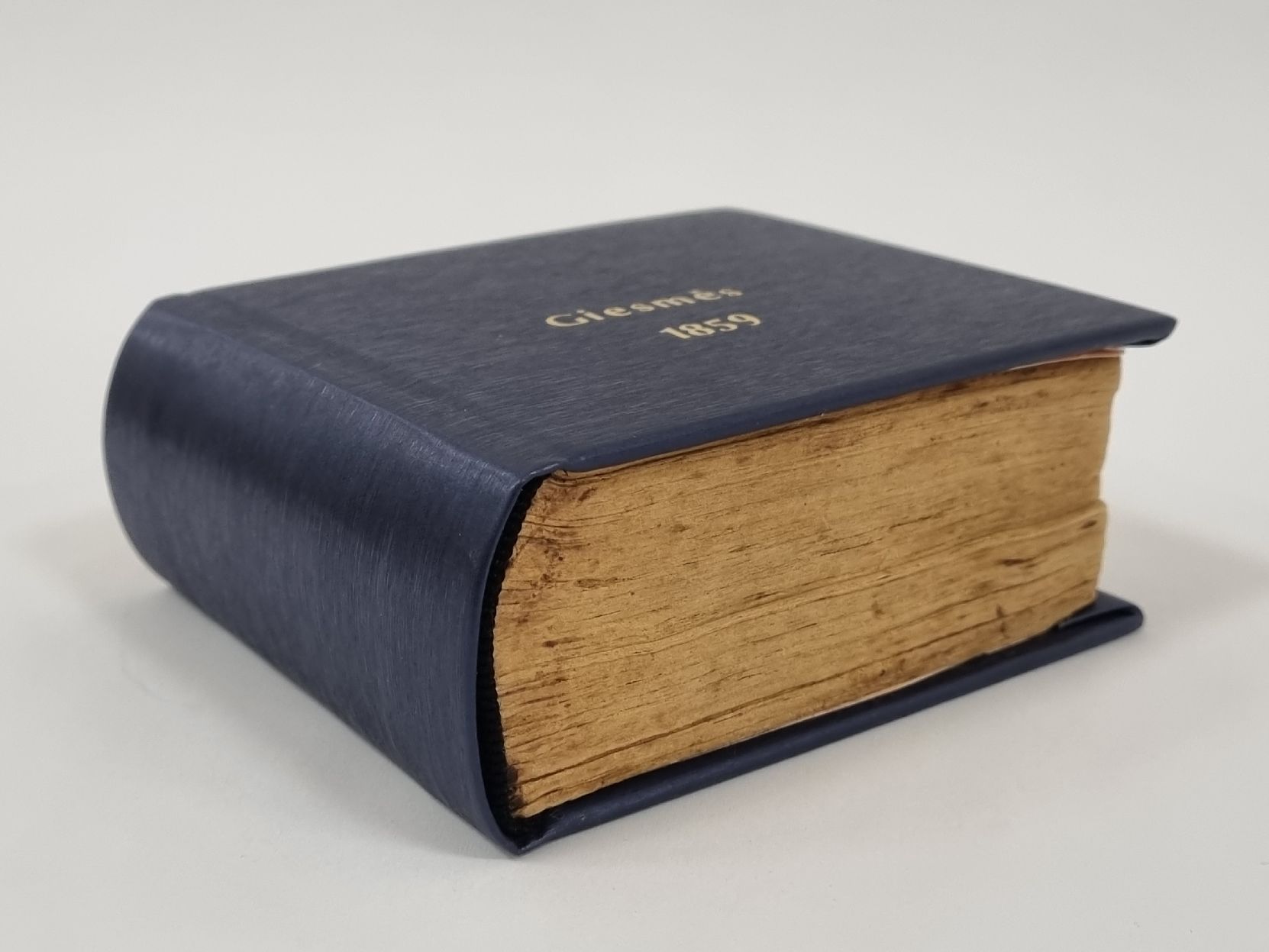

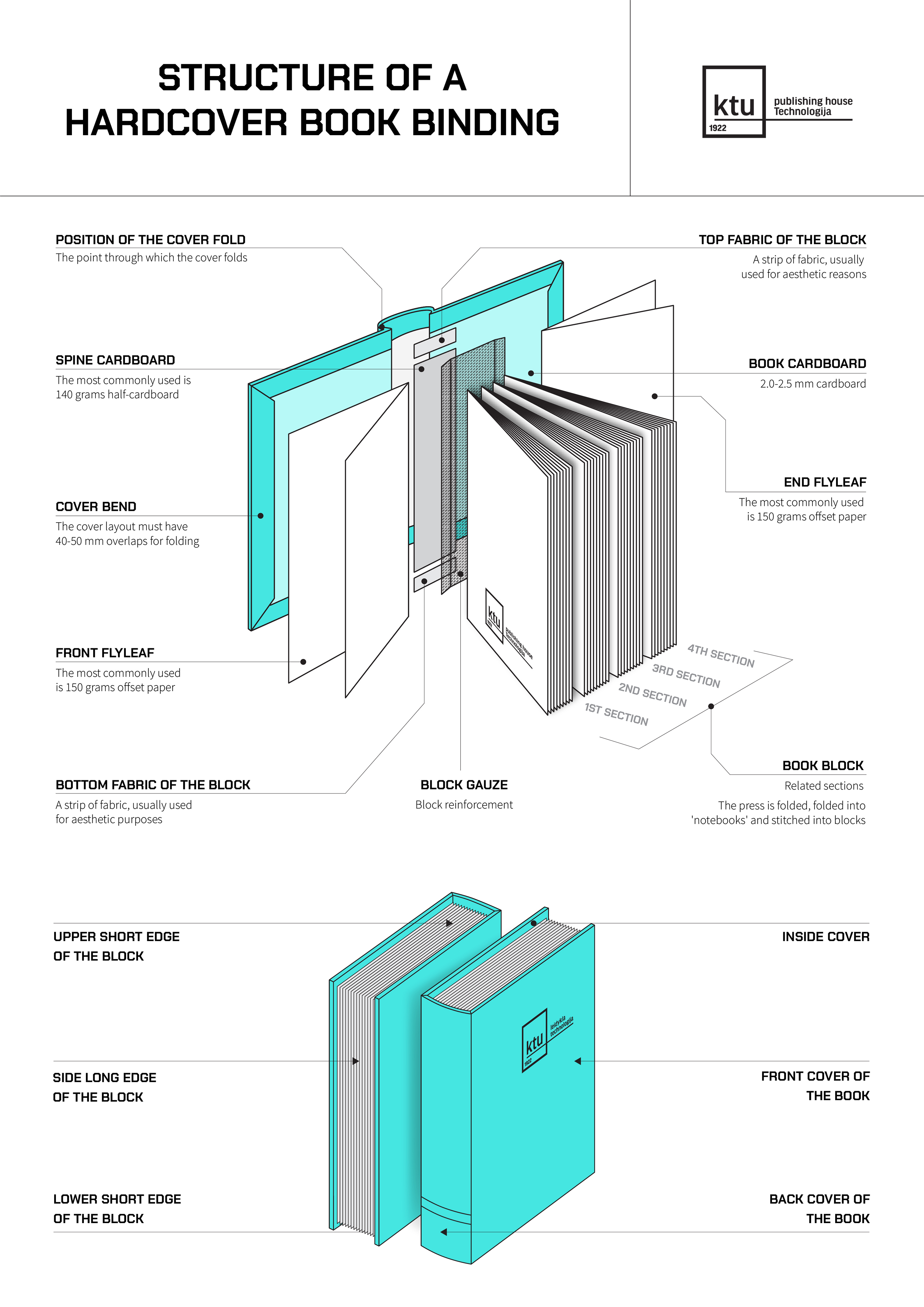

Would you be interested in sewn binding, hardbacks, sewn or glued brochures, or just glued brochures and sewn books? Whatever your requirements, “Technologija” is here to help.